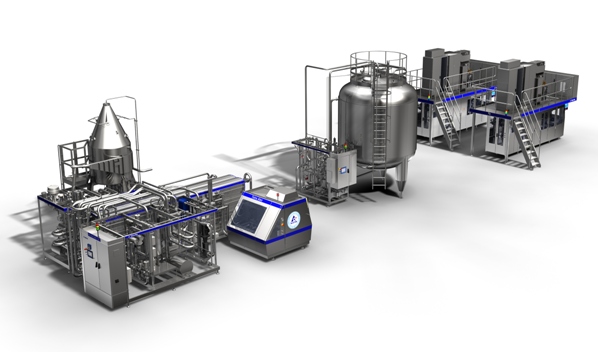

Nowadays, the main section of any milk processing plant is the milk processing equipments. It helps to perform the various operations and working on milk production such as storing milk, clarification, homogenization, separations, pasteurization and some other operations. In modern days, the all milk processing equipments have become more advanced with some latest and unique techniques. These advanced hi-tech machines are very useful for farmers for good quality milk production without more human efforts. The milk processing equipment is designed and developed to consider all farmers’ needs. The milk processing machines have a great role to make dairy industry one of the major food industries all over the world. There are various milk processing machines helpful in dairy plants to produce best products like cheese, milk, butter, yogurt, ice cream and much more similar products.

Milk equipments, process and operation in dairy plants:

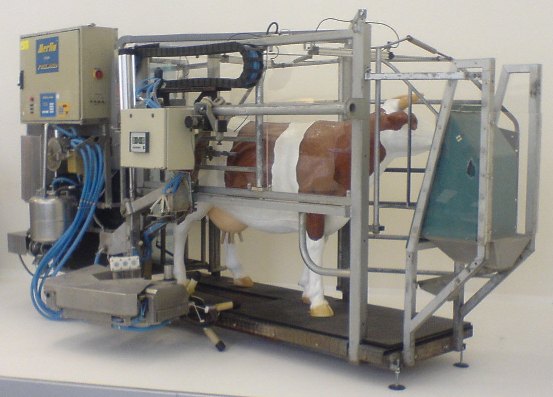

Automation: It is the process or solution to control dairy respective operations, equipments and lines.

Pasteurization: The pasteurizers equipments are used to pasteurization process for heat treatment of products to kill bacteria and reduce enzymatic activity.

Mixing: Mixing is a high complex operation for emulsifying, dispersing, dissolving the powder and liquid ingredients into a liquid medium.

Milk separators: The milk separators are very useful in milk processing plants to ensure the texture and excellent quality of products and elevated performance of skimming milk by preventing intake of destructive air.

Standardization: The standardization is the main process in milk production whereby the protein, total solids, fat and solids non-fat have previously separated from a product.

Homogenization: The homogenizers is used to perform this operation for achieving a variety of different results, for improving the taste, texture and viscosity of cream or juice-based drinks, for preventing a cream line and sedimentation in milk products, for preventing the separation of the whey in yogurt.

Sugar Treatments: It is the process to make low-grade sugar suitable for use in food. There is various type of sugar treatment performed by milk equipments.

Milk tanks: The milk tanks are the main part of the dairy plants used for storing or receiving raw milk, skimmed milk and cream.

Moreover, these milk processing equipments are helpful to make good quality cheese by performing various operations like block forming, draining, mellowing, mold filling, liquid filled cheese, whey handling and pasteurization. Similar to ice cream production, the milk processing machines are helpful to perform various operations like mix preparation, extrusion, filling, freezing, handling, hardening, inclusion and at the last packaging. These all advanced hi-tech machines play the main role for farmers to get leads and success in dairy business.