Nowadays, most of the people are non-vegetarian and like to eat nonveg. Therefore, the use of meat processing machines has become very common in the food industry and at home. These machines are manufactured with highly advanced techniques and user-friendly features, which make it useful for people in different ways for meat processing. These machines are helpful to perform various operations such as mixing, tumbling, chopping, comminuting, salting curing, cutting, fermentation, drying, heat treatment and much more. The meat processing machines are useful to decrease harmful bacteria and make ready to meat for human consumption. In modern days, the meat processing equipment can be mechanized easily. There are some common meat processing machines in the food industry for home use. It is easily available in the market in various shapes and sizes.

Some most common meat processing machines:

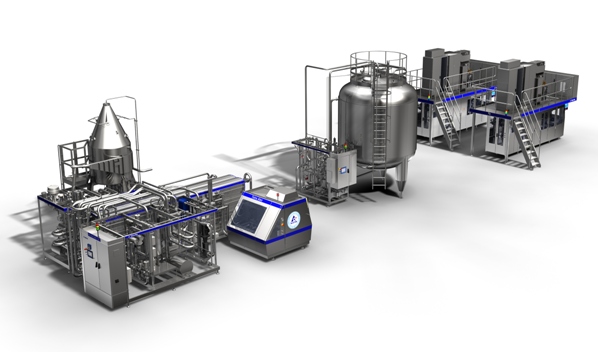

The meat processing machine is useful to perform small scale, medium and large scale operations. In modern days, meat machines are designed for high functionality, long-lasting, highest hygiene, simple cleaning, safety and easily operation. There are some meat processing machines are very commonly used in food industries and at homes.

Meat grinder: A meat grinder is the only kitchen appliance that is most widely used for cutting, mixing, chopping or mincing to cook meat, fish, vegetables and similar food. The meat grinder is the popular meat processing machinery in meat industry that broadly use for both professional and personal purpose. Now, it’s common to have own meat grinder at home to make delicious meat recipes very easily. This meat machine is helpful to fragment or cuts meat into slighter or small pieces before start cooking. It is flexible and comfortable to use of chopping for both hard and soft meats like chicken, rabbit, duck, pork, lambs, beef, buffalos and more similar meat.

Meat Mixer: The meat mixer is another meat processing equipment that is very useful for various process of food such as mixing, whipping and beating. There are two types of meat mixers available in the market stand mixers and hand mixers. There are numerous ranges of meat mixers used in professional food business. The meat mixer is suitable for all kinds of kitchen and is manufactured with many features like easy to clean, dismantle or re-assemble. It is very useful to make cooking easy.

Meat Timber: The meat timber is one of the most demandable meat processing equipments used by people for professional and personal purpose. The meat timber manufactured with metal blade and sharp teeth that make it very powerful to cut any sizes of meat in different-different pieces. These machines play wide-flexible role as the automatic and robotic solution.

Meatball Forming Machine: Last, but not least, the meatball forming machine is most widely used by people for making meatballs, fish balls, chicken meatballs, pork balls, mutton balls, beef balls, shrimp meatballs and so on. These meat machines are helpful to provide brilliant quality in size and the taste of meatballs.

Nowadays, there is some more meat processing machines available in market that becoming very popular and playing the best role in meat industry with their advanced features.